To prevent noise and vibrations from being transmitted to the wall or pipe system, every profivac has a vibration-free connection piece.

You will never again inhale 100 times the amount of airborne dust when you have to empty the dirt tank, because even when disposing of the dirt, the obligatory dust cloud is now a thing of the past. The dirt tank can be used with our dust bag including Maximizer (cardboard). This means you can collect everything in one bag for disposal. In addition, the Maximizer ensures that the entire volume of the dust container is used.

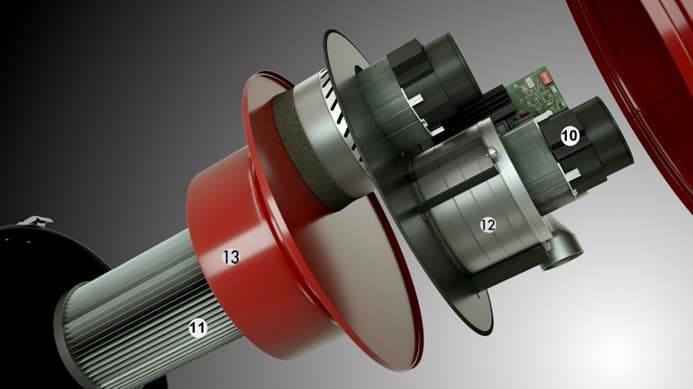

The electric motors are cooled by openings in the cover, through which clean ambient air is drawn in to evenly cool the motor compartment. As the filter and dirt tank are completely separated from the motor compartment, the motors are fully protected from heated intake air containing residual dust. Overheating is impossible. This increases the service life of the motors by years.

The sucked-in air containing fine dust, dirt and stones is directed into the cyclone filter chamber at a speed of over 120 km/h. In the round profivac central vacuum cleaner, cyclone separation ensures that all the dirt is pressed against the outer wall by the rotating movement and transported downwards into the air-calmed dirt container.

The profivac central vacuum cleaner housing is made entirely of steel, chromated and powder-coated. All components are earthed to prevent static charging.

A low-voltage cable for switching on/off can be installed here; with WIRELESS, this work is not necessary at all.

For easy opening and closing of the dirt container.

After maintenance has been completed, press the reset button to clear the display on the handle. The device can be switched on and off manually using the reset button on the control unit.

The volume is measured at a distance of 1 m (DIN EN ISO 3744). Profivac complies with the increased sound insulation requirements according to SIA 181!

Carbon brushes conduct electricity to the motors. Experience has shown that these need to be replaced depending on the number of hours of operation (approx. every 10–15 years). Once the carbon brushes have been replaced, the motors will continue to run for many years.

Polyester lamella filter. The filter is cleaned every 2 to 3 years. It can be knocked out, vacuumed or blown out. A new filter only needs to be purchased after approx. 10 years. If the filter is washed, it is important that it has at least 4 days to dry. It may only be reinserted after this time. BIA C category filter, (smaller than) 0.2 µm, ZH1/407. Our filter is suitable for clean rooms. Exhaust air to the outside is not necessary if the device is hung in a garage or technical room (no heat loss).

The number one with the best suction power! The profivac 430 always has two bypass motors, as used by professionals. Thanks to its world-class suction power (vacuum: 45 kpa/4500 mm water column), you can cut your vacuuming time in half – the suction power is more than 50% higher than most single-motor central vacuum cleaners.

Smooth start-up of the motors

The soft start ensures that the motors do not receive the full current at once. The motors are slowly supplied with power. This results in less wear and tear during start-up. The motors therefore have a much longer service life.

Motor run-on

After switching off, the motors continue to run for approx. 2 seconds. This removes all dirt from the pipe system. Virtually no dirt remains in the system.

Bypass motor technology

Our suction turbines are additionally protected by a bypass so that the warm air containing fine dust particles is directed past the motors. In cheaper, so-called through-flow motors, the contaminated air is blown through the motor, which has an extreme effect on its service life and warranty period. For this reason, we exclusively use bypass motors. This allows us to increase the service life of our motors and devices many times over.

The filter is equipped with an impact protection system, which prevents damage to the filter from coarse suction debris!